Manned spacecraft are no longer launched here.

But the demand for craft-brewed beer from the Florida Beer Company is soaring. In Cape Canaveral, the American spaceport, the starting point for the Moon landings and numerous space missions, the privately owned brewery has accordingly expanded its operations in a newly modified hall. For the brewing process, Florida Beer uses a CombiCube B, Steinecker’s modularised brewhouse concept, which not only ensures a minimised installation time, but also if necessary fast and uncomplicated upsizing. Proprietor Jim Massoni is more than pleased.

It’s not only large breweries that merge and consolidate, that are facing ruin or are being taken over. In the early years, particularly, and the late 1990s, some founders of craft breweries learned a painful lesson: they were too inadequately capitalised to survive on the market. A fate suffered not least by the Indian River Brewing Company, founded in 1996 and located in the town of Melbourne, 50 kilometres to the south of Cape Canaveral, Florida. Two rivers come together in this sun-kissed town surrounded by water, the Indian River and the Banana River, and flow onwards into the Atlantic.

A new and exciting life as a micro-brewer

The micro-brewery produced two beers and an apple cider, and was only producing 1,000-barrels. In 2000, it got into financial difficulties. Back then, Jim Massoni was still working in California’s Silicon Valley as an executive at internet technology pioneer BEA Systems, Inc. In 2003 he became aware of the brewery through a friend with close ties to the Indian River Brewing Company and he learned of the brewery’s difficulties. After carefully evaluating the opportunity he and his partner, Ed Scott, decided to purchase a majority shareholding. This marked the start of a new and exciting life for him as a micro-brewer. He had heard about the boom for craft breweries in the USA, of course, and sensed that it was still the right time to invest. Just two years later, in 2005, the newly founded Florida Beer Company took over the Ybor City Brewing Company in Tampa, Florida, which in its turn had purchased the Key West Brewery and the Hurricane Reef Brewery in Miami beforehand. At a stroke, the Florida Beer Company’s output was increased by around 8,000 barrels.

Capacities come up against their limits

Jim Massoni upgraded the brewing facility in Melbourne, invested in bottling kit, marketing, sales and distribution, purchased an additional warehouse. On the technical side, he was most capably assisted by his brewmaster Jack Owen, who had been with the firm since 1996, and later on also by José Avala, a former brewmaster at the prestigious Craft Brewery Samuel Adams. The two brewers developed new beer styles, created new recipes. Today, the Florida Beer Company produces 18 different beers, including six seasonal specialties and three ciders (which are becoming ever more popular in the USA): apple cider, pear cider, blackcurrant cider. The most popular beer, accounting for 30 per cent of the total output, is Key West Sunset Ale with 28 bittering units, followed by the German-style Florida Lager.

Showcase brewery

The company decided to invest some more money and move the brewery, directly to Cape Canaveral. The new brewery building, the former Florida location of Chrysler Corporation Ballistic Missile and Space Activities, is situated almost directly next to a highway that every year brings around three million people from Orlando to the beaches on the Atlantic coast. Another three million people board cruise liners every year in nearby Port Canaveral, like those of the Disney World fleet. And about 200,000 cruise passengers who come from other ports make a one-day stopover here with outings. So every year more than six million people pass by the brewery. And Jim Massoni wants to persuade as many as possible of them to visit his brewery, taste his beers, and hopefully buy some, thus boosting their sales and their popularity. This is why a spacious tasting lounge is a very important element in the concept for the new brewery.

Modularised compact-size brewhouse

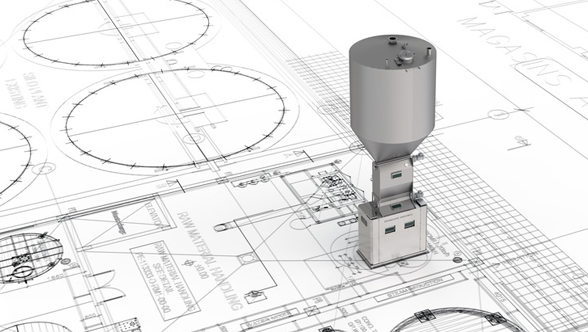

Without a doubt, the main attraction at the heart of the new brewery is the CombiCube B brewhouse. Breweries with a brew size of 40 to 105 hectolitres of cast wort had hitherto not been able to benefit properly from Steinecker’s innovative technology. The customised systems above this rating were not really amenable to use in the lower output range. But since Steinecker wanted to offer the right technology for each and every brewery, the firm’s creative minds set themselves to modify the large-scale concepts to suit a downsized output category. High-performance technology downscaled to suit mid-tier requirements – this means that medium-sized companies like America’s craft breweries can also benefit from top-quality, dependably operating technology from Krones.

“I obtained quotations from four different brewhouse manufacturers, one American firm and three German ones. For a variety of reasons, in the end the CombiCube B from Steinecker stood out as the right choice for both me and the entire team”, explains Jim Massoni. “What I found particularly interesting was the compact frame construction, which enables it to be prefabricated in the factory, making for shorter installation and commissioning times. The CombiCube also scored highly with its modularised design, which means it’s very easy to upsize its capacity. The small footprint, the quality of the craftsmanship, and modern, efficient Stromboli boiling technology, and not least Steinecker’s excellent reputation were additional very attractive arguments.”

Second mash-wort copper would double the annual output

The CombiCube B brewhouse at the Florida Beer Company comprises three vessels for 90 barrels of hot wort: a mash-wort copper featuring Stromboli, a lauter tun and a whirlpool. Here the brewery produces four brews a day in an infusion mash process. A Variomill wet mill supplies the malt grist. “The CombiCube B now offers us a capacity of well over 90,000 barrels. With an additional mash tun, we could very easily triple the number of brews a day, for three times the annual output. Thanks to the modularised design. It took only four months from placing the order before the CombiCube B was delivered, which was pretty fast compared to a traditional-type brewhouse”, says the proprietor.

Extremely confident

Jim Massoni still sees plenty of scope on the market for expanding his beer sales. Currently, Florida itself accounts for about 75 per cent of total turnover. In this state, there were 54 craft breweries operating in 2011; Florida Beer Company is the biggest of them. Florida is the USA’s third-biggest market for beer, but for a long time consumption of craft beers lagged behind the levels in other states. This did not change until recently. Now, the growth rate for craft beer consumption in Florida exceeds that in all other states of the USA. “Here in the Sunshine State we have a lot of tourists. And more and more people are turning away from mass taste, and asking for local food, local fish and local beer. When the big breweries lose one per cent, the craft breweries gain many times that”, is Jim Massoni’s assessment of the situation. And the Florida Beer Company is expanding beyond the state borders, with distribution in Alabama, North and South Carolina, Virginia, Maryland, Washington DC and New York .

In the summer of 2012, the Florida Beer Company produced its first brew in its new CombiCube B. With the capacity now available, the craft brewery is finally able to meet soaring levels of demand. And will find out at last which of its numerous beers is actually the most popular. To quote Jim Massoni: “We’re extremely confident for our beers and our market.”

Wouldn't that be something for you too?